Attleboro High School Sets New Standards in Efficiency with Belimo EPIV

Attleboro High School recently underwent a significant transformation with the construction of an all-new $260 million campus, representing the largest municipal undertaking in the history of Attleboro, Massachusetts. Breaking ground in October 2019, and opening its doors for the first time in September 2022, the new AHS is a four-story edifice encompassing 475,000 square feet with the capacity to accommodate 1,725 students.

Project Motivation

Massachusetts is considered a leader in the United States when it comes to energy efficiency standards, and the state provides financial incentives to districts that build highly efficient schools. The new construction was expected to conform to the Massachusetts Ninth Edition of the MA State Building Code 780 guidelines, which closely follows the energy efficiency requirements of ASHRAE 90.1-2013.

“The Green Schools Program is a system of reimbursement that provides monetary benefits to schools that opt for sustainable, high-performance designs,” says Derek Bride, Principal at Consulting Engineering Services (CES). “The Green Schools Program was certainly on our minds from the start of the project, and we wanted to ensure they’d be eligible for benefits,” Derek said.

Under the Green Schools Program, the Massachusetts School Building Authority (MSBA) rewards school districts an additional 2% reimbursement for projects that meet its sustainable building design requirements. In the case of AHS, this would mean a reimbursement upwards of $4.0 million.

All new schools in Massachusetts are required to exceed ASHRAE 90.1 by at least 10%. Green Schools, however, must achieve LEED® certification, which requires that buildings exceed the energy efficiency requirements of the ASHRAE Standard 90.1 by at least 20%.

System Design

With overall budget considerations in mind, CES originally designed a traditional pressure dependent HVAC system. “Engineers often assume that going pressure independent is going to be too costly in terms of parts, but it’s not always the case,” said Paul Carter from Arden Engineering Constructors/Earthwise Energy Technologies, the mechanical and controls contractor on the job.

Pressure independent HVAC systems offer substantial benefits over traditional pressure dependent designs, providing improved energy efficiency and lower maintenance costs over time. But also, PI systems can save money during the construction phase.

“In a pressure independent system, the need for circuit setters and manual balancing is eliminated because each control valve regulates its own flow rate regardless of pressure changes. This reduces both materials and installation costs,” Paul explained.

Familiar with Belimo’s pressure independent control valve offering, Paul quickly concluded that the Belimo EPIV offered the perfect balance of performance and affordability for the larger valves in the system. “The EPIV is great for managing higher flow rates. The integrated electronic flow sensor uses a robust control algorithm which talks to the actuator and adjusts the valve to compensate for pressure variations, performing dynamic balancing. This ensures system efficiency.”

Paul Carter, General Manager of Arden /Earthwise, reviews system settings using the Belimo Assistant App.

The EPIV assembly integrates a characterized ball valve, a high-performance actuator, a flow sensor equipped with glycol compensation, a temperature sensor, and flow control logic all-in-one unit. Despite fluctuations in system pressure, the EPIV maintains the flow set point by adjusting the characterized control valve based on the measured true flow.

“We used the EPIV in parts of the system where the flows were above 9 GPM, about 62 assemblies in total. But, for flow rates under 9 GPM, we went with an affordable, compact mechanical PI solution from Belimo, the 2-way ZoneTight PIQCV,” Paul explained.

The Belimo ZoneTight PIQCV is a mechanical pressure independent control valve with an ultra-small form factor, making it ideal for tight spaces. It combines a spring-action differential pressure regulator with a 2-way valve to ensure a consistent flow regardless of any variations in system pressure. The PIQCV ‘s actuator operates at just 0.3W, which conserves energy and transformer power. 223 PIQCVs were used throughout the system at AHS.

Added Savings

While pivoting to a pressure independent design saved the costs of circuit setters and manual balancing, additional savings were needed to keep the project under budget. Paul reached out to PJ Qvarnstrom, RetroFIT+ Business Manager at Belimo, to see if other savings could be achieved. “Piping packages are a great way to save the customer some money on labor, and when they make sense to do, they can really help push a job over the finish line,” explained PJ.

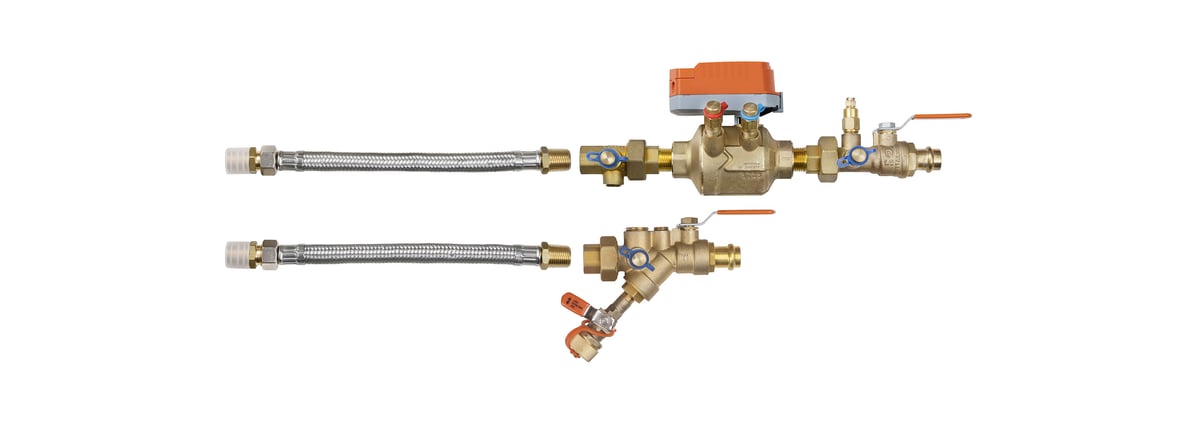

“PJ approached me about the Attleboro High School project, which called for hundreds of EPIV and PIQCV assemblies that needed a complete solution — including unions, isolation valves, and isolation strainers,” said Aaron Nobel, Piping Packages Product Specialist for Belimo. “We were able to provide piping packages for these valves which cut down on labor by up to 80%. Plus, the packages take up half the space compared to standard individual components.”

Belimo piping packages saved on labor costs, keeping the project under budget (PIQCV shown)

Belimo was able to deliver nearly 400 pre-assembled piping packages, creating the additional savings needed to deliver Attleboro High School a more efficient, lower maintenance, pressure independent HVAC system for about the same cost as the originally designed pressure dependent system.

Customer Satisfaction

“Thanks to Belimo, we were able to deliver the customer a far superior system for the same amount of money,” Paul added. “Using PI valves cut costs on parts and manual balancing, plus the piping packages really saved on labor,” he said.

“The current projected energy usage in the building is 32 kBTU/SF, which is 36% better than the baseline,” according to Dave Hillburn, a Senior Mechanical Engineer at CES. “That well exceeds the performance required to become LEED certified and receive the 2% reimbursement. The system will run more efficiently, will be easier to maintain, and will save the school money down the line.”